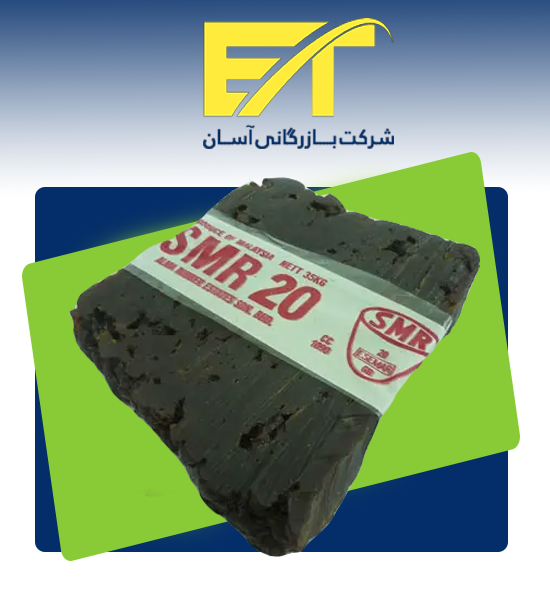

What is SMR20 Natural Rubber?

SMR20 Natural Rubber (Standard Malaysian Rubber 20) is a type of natural rubber extracted and produced from rubber trees (Hevea brasiliensis). This particular type of rubber is produced in Malaysia.

Step by Step with the History of SMR20 Rubber

The history of SMR20 natural rubber dates back to the production and development of rubber in Malaysia. In the 1920s and 1930s, Malaysia became one of the largest producers of natural rubber in the world, and great attention was paid to improving the quality and standards of production of this material.

Rubber tree cultivation: In the early 20th century, Malaysia began cultivating rubber trees (Hevea brasiliensis) as a key industry. These trees were highly regarded for their special characteristics, such as the production of high-quality latex.

Definition of standards: As production increased, the need for standardization of natural rubber was felt. In this regard, SMR20 was introduced as one of the specific and high-quality standards for natural rubber in Malaysia. This standard helped manufacturers to provide higher quality products.

Global Market Development: In the following decades, with the increasing demand for natural rubber in various industries such as tires, rubber and adhesives, SMR20 became one of the key products in the global market.

Innovation and Research: Over time, research and development continued to improve the production processes and quality of natural rubber, and SMR20 was recognized as an important material in various industries.

SMR20 Natural Rubber Price

The price of SMR20 natural rubber depends on various factors such as exchange rates, quality of raw materials, raw material extraction costs, transportation, labor costs, etc. and you can inquire online from ETD Company. To buy all types of natural rubber, contact our sales and support experts.

Inquiry about the current price of SMR20 rubber

To purchase and inquire about the current price of SMR20 natural rubber, contact the support experts of the Minister of Polymer. If you intend to purchase SBR 1502 natural rubber or PBR synthetic rubber, please contact us.

SMR20 Natural Rubber Specifications

SMR20 natural rubber has properties that make it suitable for various applications. One of its key features is its high tensile strength, which allows it to withstand heavy loads. SMR20 also has good flexibility that is maintained even at low temperatures. This property makes it highly effective in various weather conditions and in industrial applications, especially in automotive and heavy machinery tires.

In addition, SMR20 natural rubber has good resistance to abrasion and corrosion, which makes it an ideal choice for the production of long-lasting tires. This rubber is also resistant to heat and environmental factors, which makes it perform well in harsh conditions.

The role of SMR20 natural rubber in the production of rubber materials

SMR20 natural rubber is used in the production of a variety of special and functional tires, including:

Production of car tires with SMR20 natural rubber

Passenger tires: SMR20 is used as the main ingredient in the production of high-performance tires for passenger cars.

Heavy tires: It is also used in truck and heavy vehicle tires.

Production of industrial tires with SMR20 natural rubber

Specialty tires for machinery: It is used in the production of industrial tires and heavy machinery, due to its high strength and durability.

Other special products

Medical tires: It is used in the production of medical equipment and health products, due to the purity and hygienic properties of SMR20.

Electrical insulators: It is also used as an insulating material in some electrical applications.

Production of sports tires with SMR20 natural rubber

Sports products: It is also used in the production of balls, sports shoes and other sports equipment.

The use of SMR20 helps to improve the performance and lifespan of products due to its unique properties.

Extraction of SMR20 natural rubber

The SMR20 natural rubber extraction process usually involves making special cuts in the bark of the tree, called “leaching”. These cuts allow the latex, or liquid containing the rubber, to be extracted. After collection, the latex undergoes various processes, including purification and drying, to produce high-quality natural rubber.

The SMR20 natural rubber production process must be carried out with care and compliance with certain standards to ensure the final quality of the product. At this stage, additives may be added to the rubber to improve its physical and chemical properties.

Advantages of using SMR20 natural rubber

SMR20 natural rubber has several advantages that make it a desirable and selectable option for various industries. In the following article from Asan Trading Company, we will mention some of these advantages:

High quality of SMR20 rubber

SMR20 performs better than many other rubbers due to its purity and high quality. This quality makes the products produced with this rubber more durable and strong.

Resistance of SMR20 rubber to abrasion

This type of rubber has high tensile strength, which allows it to withstand heavy loads. Also, SMR20 has good resistance to abrasion and corrosion, which is why it is very efficient in car tires and industrial machinery.

Performance of SMR20 rubber at different temperatures

SMR20 has high flexibility and maintains its performance at low temperatures. This feature makes it perform well in different weather conditions and in various applications.

Durability and long life

Products made from SMR20 have a longer life due to its physical and chemical properties. This durability helps reduce maintenance and replacement costs.

Resistance to environmental factors

SMR20 is resistant to UV and other environmental factors. These features make it suitable for use in outdoor applications and in harsh conditions.

Environmental compatibility

SMR20 natural rubber is a renewable resource and has a lower impact on the environment than synthetic rubbers. This has led to its use in various industries, especially in environmentally friendly fields.

Process-ability

SMR20 can be easily processed and combined with other materials. This feature allows manufacturers to produce different products with specific properties.

Suitable for various industries

SMR20 is used not only in rubber production, but also in the medical, insulation and sports products industries. This variety of applications demonstrates the high capabilities of this type of rubber.

These advantages make SMR20 an ideal choice for manufacturers in various industries.

Differences between SMR20 Natural Rubber and Other Types of Rubber

The differences between SMR20 natural rubber and other types of natural and synthetic rubber depend on their characteristics, applications and physical properties. Below, we will examine some of these differences:

Source of production

SMR20: It is extracted from rubber trees (Hevea brasiliensis) in Malaysia and is considered a type of natural rubber.

Synthetic rubber: It is usually produced from chemicals such as styrene and butadiene.

Quality and purity

SMR20: It has high purity and consistent quality, which makes it suitable for certain applications.

Other rubbers: May vary in quality and purity and therefore may not be suitable for some applications.

Physical properties

Tensile strength: SMR20 natural rubber usually has a higher tensile strength than some synthetic rubbers.

Flexibility: SMR20 natural rubber has good flexibility that is maintained at low temperatures, while some synthetic rubbers may harden at low temperatures.

Abrasion and Corrosion Resistance

SMR20: It has good abrasion resistance and is therefore very effective in the production of automotive and industrial tires.

Other rubbers: May perform differently in this area.

Applications

SMR20: Used as a primary raw material in the production of automotive tires, medical products, and electrical insulators.

Synthetic rubbers: Typically used in applications that require specific properties such as resistance to heat, oil, or chemicals.

Price and Availability

SMR20: May be more expensive than some synthetic rubbers due to geographical limitations and manufacturing process.

Synthetic rubbers: Typically more readily available and may be less expensive.

Disadvantages of SMR20 Natural Rubber

Despite its many advantages, SMR20 natural rubber also has disadvantages and limitations that can affect its selection and use. Here are some of these disadvantages and limitations:

Sensitivity to weather conditions

SMR20 natural rubber is highly affected by weather conditions. Changes in temperature, humidity, and rainfall can affect its quality and performance. In adverse weather conditions, the quality of the rubber may decrease.

Production limitations

The production process of SMR20 natural rubber requires specific conditions. To produce high-quality rubber, careful management of the fields and harvesting processes is required. This can lead to increased costs and reduced ability to produce on a large scale.

High price

Due to the complex harvesting and production processes, the price of SMR20 natural rubber is usually higher than synthetic rubbers. This can be a barrier for some manufacturers looking to reduce costs.

Storage Limitations

Natural rubber requires special storage conditions due to its moisture absorption and temperature changes. These conditions can lead to additional storage and warehousing costs.

Low resistance to some chemicals

SMR20 is sensitive to some chemicals and oils and may be less resistant to them. This can pose limitations in some applications, especially in the automotive industry.

Shorter life compared to some synthetic rubbers

In some conditions, the useful life of SMR20 may be shorter than that of synthetic rubbers. Synthetic rubbers may perform better, especially in environments exposed to chemical agents or very high temperatures.

Competition between SMR20 and synthetic rubber

Due to technological advances in the production of synthetic rubbers, these products may offer certain properties, such as resistance to heat and chemicals, that SMR20 is unable to provide.

Need for advanced technologies

To obtain the best quality and performance from SMR20, there is a need for advanced technologies and innovative processes in its production and processing. This can be a challenge for manufacturers who do not have access to these technologies.

Chemical composition of SMR20 natural rubber

The chemical composition of SMR20 natural rubber mainly consists of polyisoprene, which is a natural polymer. Below we will mention more details about the chemical composition of this type of rubber:

Polyisoprene

Molecular structure: Polyisoprene is a polymer that is made up of repeating units of isoprene (C5H8). These units are linked together in a chain and form the main structure of natural rubber.

Properties: This polymer has high elasticity, flexibility and resistance to pressure, which are key characteristics of natural rubber.

Additional compounds

In the production process of SMR20, additional compounds may be added to it to improve its physical and chemical properties. These compounds include:

Stabilizers: To increase resistance to environmental factors and UV.

Fillers: Such as carbon black or silicates that help improve mechanical and thermal properties.

Facilitating agents: Which help improve the production process and performance of the rubber.

Impurity level of SMR20 natural rubber

In the production of SMR20 natural rubber, there may also be impurities that can affect the quality of work and the final properties of the rubber. These impurities may include proteins, sugars and other substances.

Ratio of isoprene to other compounds

In SMR20 natural rubber, polyisoprene usually makes up about 95% of the compound. This ratio causes the rubber to have desirable elastic and mechanical properties.

What factors affect the lifespan of SMR20 natural rubber?

The lifespan of SMR20 natural rubber depends on several factors that can affect its performance and durability. Here are some of these factors:

Environmental conditions

Humidity and temperature: Natural rubber is highly affected by atmospheric conditions. Humidity and temperature can affect its quality and lifespan. In very hot and humid conditions, rubber may degrade more quickly.

UV light: Direct sunlight and UV rays can damage the polymer structure of rubber and reduce its lifespan.

Chemical composition

Purity and quality: The quality and purity of SMR20 rubber play an important role in its lifespan. High-quality rubber usually has a longer durability and useful life.

Presence of impurities: Impurities and additional compounds added to rubber can affect its mechanical and chemical properties, and therefore its lifespan.

Type and method of use of SMR20 natural rubber

Loading and pressure: The amount of load and pressure applied to the rubber during use can have a great impact on its lifespan. Excessive loading may lead to its premature failure.

Operating environment: Use in harsh chemical or mechanical environments can contribute to reducing the lifespan of the rubber. For example, exposure to corrosive chemicals can cause serious damage to the rubber.

SMR20 rubber storage and handling methods

Storage conditions: The manner and conditions in which the SMR20 rubber is stored can also have a great impact on its lifespan. Storage in dark and dry places usually helps maintain its quality.

Storage time: Long storage times may lead to decomposition and deterioration of the rubber quality.

Production and processing processes

Production process quality: The production and processing processes used for the rubber can affect its final properties. Improper processes may result in reduced quality and longevity of the rubber.

Effects of Sunlight and UV on SMR20 Natural Rubber

Sunlight and ultraviolet (UV) radiation have significant effects on SMR20 natural rubber. These effects can result in reduced quality and shelf life of the rubber. The following are the details of these effects:

Chemical Degradation

Damage to Molecular Structure: UV radiation can damage the molecular structure of the polyisoprene in SMR20 rubber. This damage can cause the polymer chains to break, resulting in a decrease in the elasticity and flexibility of the rubber.

Free Radical Generation: UV radiation can lead to the production of free radicals, which can initiate unwanted chemical reactions and contribute to further degradation of the rubber.

Reduced mechanical properties

Reduced tensile strength: Sun damage can lead to a reduction in the tensile strength of rubber, which can affect its performance in industrial applications.

Increased brittleness: Rubber exposed to UV light may become more brittle and therefore more vulnerable to mechanical stress and strain.

Color and appearance changes

Color changes: Exposure to sunlight can cause SMR20 rubber to change its color and appearance. These changes in appearance may reduce the attractiveness of the final products.

Reduced transparency: UV radiation can cause the rubber to become cloudy and lose its transparency.

Reduced shelf life

Reduced shelf life: In general, prolonged exposure of SMR20 rubber to sunlight and UV radiation can reduce its shelf life. This can increase replacement and maintenance costs.

Prevention and Protection

Use of protective coatings: To reduce the effects of sunlight and UV rays, protective coatings or UV additives can be used, which help increase the rubber’s resistance to these rays.

Proper storage: Storing SMR20 rubber in dark, dry places away from direct sunlight can help maintain its quality and longevity.

Factors Affecting the Price of Natural Rubber SMR20

The price of natural rubber SMR20 is affected by several factors that can change in global and local markets. Here are some of the most important of these factors:

Supply and Demand

Supply: The number of rubber trees and the amount harvested each year can affect the price. When supply decreases, the price increases.

Demand: The demand for natural rubber in various industries, especially in the rubber industry, has a great impact on the price. Increased demand can lead to an increase in price.

Weather and Climate

Weather Impact: Adverse weather conditions, such as storms, heavy rainfall or drought, can affect the rubber harvest. These conditions can lead to a decrease in production and, as a result, an increase in price.

Production Costs

Labor Costs: Labor costs in producing countries can affect the price of rubber. Increasing wages may lead to an increase in production costs and, consequently, the final price.

Raw material costs: Costs associated with raw materials and production processes can also affect the price.

Global market fluctuations

Exchange rates: Fluctuations in exchange rates can affect the price of rubber exports and imports. Changes in the value of national currencies can lead to changes in global prices.

Competition with synthetic rubbers: If the price of synthetic rubbers decreases, the demand for natural rubber may decrease, which can lead to a decrease in the price of SMR20.

Government policies

Supportive policies: Government support for rubber producers, such as subsidies and financial facilities, can help reduce prices.

Export restrictions: Restrictive export policies in producing countries can affect supply and price.

Rubber quality and type

Product quality: The quality of SMR20 rubber has a direct impact on the price. Higher quality rubber usually has a higher price.

Type of rubber: Different types of natural and synthetic rubber can also affect the price.

Technology and innovation

Technological advances: Innovation in production and harvesting processes can help reduce costs and ultimately lower prices.

Optimizing cultivation methods: Improving cultivation and harvesting methods can lead to increased production and lower prices.

In which country is SMR20 natural rubber produced?

SMR20 natural rubber is mainly produced in Malaysia. Malaysia is one of the largest producers of natural rubber in the world, and SMR20 is one of the famous natural rubber standards in the country.

Reasons for producing SMR20 rubber in Malaysia

Geographical conditions: Malaysia has a suitable environment for growing rubber trees (Hevea brasiliensis) due to its warm and humid climate.

Advanced Technology: The rubber industry in Malaysia benefits from modern technologies and optimization methods that help increase the quality and quantity of production.

Supportive Policies: The Malaysian government has support and incentive programs for rubber producers that help develop this industry.

Other countries producing SMR20 rubber

In addition to Malaysia, other countries such as Indonesia and Thailand also produce natural rubber, but SMR20 is especially known as a standard from Malaysia.

Is SMR20 rubber produced in Iran?

SMR20 rubber is not produced specifically in Iran. Due to its geographical and climatic conditions, Iran is not suitable for growing rubber trees (Hevea brasiliensis), and for this reason, natural rubber production in the country is limited.

Rubber Status in Iran

Dependence on Imports: Iran is mainly dependent on imports of natural and synthetic rubber from countries such as Malaysia, Indonesia, and Thailand.

Research and Development: Some projects and research in the field of rubber cultivation and production are underway in Iran, but they have not yet reached an industrial scale.

Alternatives: In the rubber industry and its related products, Iran has increasingly turned to the use of synthetic rubbers and various mixtures.

Shelf Life of SMR20 Rubber

The shelf life of SMR20 natural rubber in storage depends on several factors that can affect its quality and performance. The following are the factors and tips related to storage:

Storage conditions for SMR20 natural rubber

Temperature: SMR20 rubber should be stored at appropriate temperatures (usually between 15 and 25 degrees Celsius). High temperatures can lead to decomposition and deterioration of the rubber.

Humidity: High humidity can cause water absorption and change the physical properties of the rubber. The rubber should be stored in a dry and ventilated environment.

Light and UV rays

Avoid direct sunlight: Exposure to direct sunlight and UV rays can lead to decomposition of the rubber and shorten its life. It is better to store the rubber in dark places away from light.

Shelf life of SMR20 rubber

Storage time: Natural rubber usually has a certain shelf life. If the rubber is stored for a long time, its physical and mechanical properties may decrease. It is usually recommended that natural rubber be used within a certain period of time (about 6 to 12 months).

Initial Quality

Purity and Quality: The initial quality of SMR20 rubber has a great impact on its shelf life. Higher quality rubber will usually last longer.

Packaging

Use proper packaging: Proper packaging can help protect the rubber from moisture, dust, and light. Using strong, impermeable packaging materials can help increase shelf life.

What is the ideal storage period for SMR20 natural rubber?

The ideal storage period for SMR20 natural rubber is usually between 6 and 12 months. This period depends on various factors, which are mentioned below:

Storage conditions for SMR20 rubber

Temperature and humidity: If the rubber is stored in the right conditions (temperature between 15 and 25 degrees Celsius and low humidity), it may be able to be preserved for up to 12 months or more.

Light and UV rays: Avoiding exposure to direct sunlight and UV rays can help preserve the quality of the rubber.

Primary quality of SMR20 rubber

Purity and quality: High-quality rubber is usually preserved for a longer period without deterioration. Therefore, checking the initial quality can help determine the storage period.

Proper packaging for SMR20 rubber

Packaging: Using durable and impermeable packaging can help increase the shelf life of the rubber. Proper packaging can protect the rubber from moisture, dust, and other damaging factors.

Periodic Inspection of SMR20 Rubber

Regular Inspection: Periodic inspection of the rubber during storage can help identify any changes and damage. If signs of change in quality are observed, the rubber may need to be used more quickly.

What are the methods for checking the quality of SMR20 rubber?

Various methods are used to check the quality of SMR20 natural rubber, which can include physical, chemical, and mechanical tests. Here are some of these methods:

Physical Tests of SMR20 Rubber

Appearance and Color: An examination of the appearance of the rubber, including color, transparency, and the presence of impurities, indicates its initial quality.

Crystallination Time: Examining the crystallization time of the rubber can help assess its quality. Quality rubber usually has a better crystallization time.

Rubber Chemical Tests SMR20

Chemical Composition Analysis: Using techniques such as chromatography or spectroscopy can help identify the chemical compounds present in rubber and determine the presence of impurities.

Moisture Content: A measurement of the amount of moisture present in rubber, which can affect its properties.

Rubber Mechanical Tests SMR20

Tensile Strength: A tensile strength test is performed to determine the strength and resistance of rubber to stretching. This test helps assess its quality and load-bearing capacity.

Elasticity: Measuring the elastic property can indicate the quality of rubber. Quality rubber should have good elastic properties.

Natural Rubber Thermal Tests SMR20

Thermal Analysis: Thermal tests such as thermal analysis (TGA) and differential scanning calorimetry (DSC) can help assess the thermal stability and phase changes of rubber.

Environmental Resistance Tests

UV and Chemical Testing: Exposing rubber samples to UV and chemicals can help assess their resistance to environmental factors.

Mechanical Analysis

Abrasion Testing: Measuring the resistance of rubber to abrasion, which can help assess its durability and longevity.

What are the standards for measuring the quality of SMR20 natural rubber?

SMR20 natural rubber is subject to specific quality and technical specifications that help meet the needs of various industries. Here are some of these standards and specifications:

International Standards for SMR20 Natural Rubber

ISO 2007: This international standard is designed for natural rubbers and their technical specifications and includes details on quality, test methods, and storage conditions.

ASTM D 1418: This standard is related to the identification and classification of rubbers and includes the technical specifications of SMR20.

SMR20 Technical Specifications

SMR20 rubber should usually have the following specifications:

Moisture Content: Maximum 0.5% to 0.7%

Ash Content: Maximum 0.5%

Tensile Strength: Depending on the application, it should usually be above 20 MPa.

Elasticity: It should have good elastic properties that help withstand load and pressure.

Abrasion Resistance: The rubber should be able to withstand abrasion and various environmental conditions.

National Standards of SMR20 Rubber

National Standards of Iran: There may also be specific standards for natural rubbers in Iran that should be considered. These standards are usually under the supervision of the National Standards Organization of Iran.

Test Methods

The standards include specific test methods for evaluating rubber quality, including:

Elasticity and Tensile Strength Test: To evaluate the strength and mechanical quality of the rubber.

Moisture and Ash Content Test: To determine purity and quality.

Application of SMR20 Rubber in Tire and Rubber Production

SMR20 rubber is used as a key material in tire and rubber production because it has excellent mechanical properties such as elasticity and high tensile strength, which contribute to the durability and service life of the tires. Also, this rubber offers better performance in various atmospheric conditions due to its wear resistance, favorable adhesion to the road surface and thermal stability. The reduction in friction caused by the use of SMR20 also helps to improve the fuel efficiency of the vehicle, and for this reason, this material is widely used in the production of various types of tires for cars, trucks and sports bikes.

Application of SMR20 rubber in the production and manufacture of toys

SMR20 rubber is widely used in the production and manufacture of toys due to its high elastic and safety properties. This rubber gives toys flexibility and durability, while its anti-slip property makes them easy for children to play with. Also, SMR20 is a safe option for the production of children’s toys due to its naturalness and the absence of harmful chemicals. Hence, the use of SMR20 natural rubber in this industry helps in the production of quality and hygienic toys that are not only fun but also safe.

Application of SMR20 rubber in the manufacture of adhesives

SMR20 natural rubber is used as one of the important raw materials in the production of adhesives, as it has high elastic and adhesion properties that help improve the performance of adhesives. This rubber gives adhesives flexibility and resistance to breakage, so that after drying, the adhesives can adhere well to various surfaces and are resistant to pressure and tension. Also, SMR20 is a safe and environmentally friendly option for the production of industrial and household adhesives due to its naturalness and the absence of harmful chemicals. In this way, the use of SMR20 natural rubber in the manufacture of adhesives helps to produce products with high quality and performance.

The effect of cold and hot temperatures on SMR20 rubber

Cold and hot temperatures have significant effects on SMR20 rubber, which can affect its physical properties and performance. The following are the details of these effects:

The effect of hot temperatures on SMR20 rubber

Increase in elasticity: At higher temperatures, the elastic properties of rubber improve. This feature makes the rubber perform better against tension and pressure.

Strength loss: If the temperature is too high, the tensile strength of the rubber may decrease, which can lead to a risk of breakage or damage in operational applications.

Chemical decomposition: Very high temperatures can lead to chemical decomposition of the rubber and the production of free radicals that affect its properties.

Effect of cold temperatures on SMR20 rubber

Reduction in flexibility: At low temperatures, SMR20 rubber may become harder and more brittle, which leads to a decrease in its flexibility. This can affect the performance of the rubber in cold conditions.

Increased strength: At cold temperatures, the tensile strength of the rubber may improve, but this increase in strength may be accompanied by a decrease in flexibility.

Risk of breakage: As the rubber hardens at low temperatures, the risk of breakage and damage increases when subjected to pressure or impact.

What are the methods to improve the performance of SMR20 rubber at different temperatures?

Improving the performance of SMR20 natural rubber at different temperatures requires the use of specific methods and techniques that can help increase its durability, elasticity and resistance. Here are some of these methods:

Use of additives

Anti-UV additives: The use of additives that increase the resistance of rubber to ultraviolet radiation and heat can help improve performance at high temperatures.

Blended polymers: Combining SMR20 with synthetic polymers such as styrene-butadiene can help improve the mechanical and thermal properties of rubber at different temperatures.

Advanced manufacturing processes

Vulcanization techniques: Optimizing the vulcanization process can help increase the strength and durability of rubber at different temperatures. Proper vulcanization improves the mechanical properties of rubber.

Temperature control in the production process: Temperature management during the production and storage process can help maintain the properties of rubber at different temperatures.

Proper packaging and storage

Durable packaging: Using heat and moisture resistant packaging materials can help maintain the quality of rubber at different conditions.

Storage in ideal conditions: Keeping rubber at the right temperature and humidity can prevent its decomposition and deterioration.

Mixing SMR20 rubber with other materials

Compounding with nanoparticles: Adding nanoparticles to SMR20 rubber can help improve its thermal and mechanical properties.

Use of reinforcing fibers: Adding natural or synthetic fibers to rubber can increase its strength and resistance to pressure and high temperatures.

Research and development

Innovation in formulation: Research and development in the field of new formulations can help improve the properties of SMR20 rubber at different temperatures.

Periodic testing: Performing regular tests on rubber samples can help identify problems and improve performance at different temperatures.

What are the methods to improve the performance of SMR20 rubber at different temperatures?

Improving the performance of SMR20 natural rubber at different temperatures requires the use of specific methods and techniques that can help increase its durability, elasticity and resistance. Here are some of these methods:

Use of additives

Anti-UV additives: The use of additives that increase the resistance of rubber to ultraviolet radiation and heat can help improve performance at high temperatures.

Blended polymers: Combining SMR20 with synthetic polymers such as styrene-butadiene can help improve the mechanical and thermal properties of rubber at different temperatures.

Advanced manufacturing processes

Vulcanization techniques: Optimizing the vulcanization process can help increase the strength and durability of rubber at different temperatures. Proper vulcanization improves the mechanical properties of rubber.

Temperature control in the production process: Temperature management during the production and storage process can help maintain the properties of rubber at different temperatures.

Proper packaging and storage

Durable packaging: Using heat and moisture resistant packaging materials can help maintain the quality of rubber at different conditions.

Storage in ideal conditions: Keeping rubber at the right temperature and humidity can prevent its decomposition and deterioration.

Mixing SMR20 rubber with other materials

Compounding with nanoparticles: Adding nanoparticles to SMR20 rubber can help improve its thermal and mechanical properties.

Use of reinforcing fibers: Adding natural or synthetic fibers to rubber can increase its strength and resistance to pressure and high temperatures.

Research and development

Innovation in formulation: Research and development in the field of new formulations can help improve the properties of SMR20 rubber at different temperatures.

Periodic testing: Performing regular tests on rubber samples can help identify problems and improve performance at different temperatures.

بدون نظر